How to achieve grid code compliance in wind farms?

What is grid code compliance?

Grid code compliance is a common requirement for the smooth connection of any kind of power generation plant to any grid network throughout the world. Power plants must comply with regulatory specifications set out by their Transmission System Operator (TSO). This is important to make sure the operation of the network is stable and safe.

The increasing global demand for renewable energy has been making the industry thrive in the past few years. Unfortunately, the quality of electricity produced from renewable energy does not always meet the requirements of electrical standards, which makes the integration of it into power grids rather challenging.

Wind farms, wind farms everywhere

The profitability of wind farm construction increased significantly in recent years, so wind farms have been popping up all over the world like mushrooms after rain. This increase in wind farm numbers has had a substantial impact on the electric grid. Not only that wind farms have to provide excellent power to the grid they also must be able to operate without being affected by small disturbances coming from the said grid.

Harmonic distortion in wind farms

Harmonic distortion is one of the more common issues in wind power plants. This happens most of the time when turbines are manufactured inexpensively and thus do not meet all grid requirements. This can cause the system operator to refuse to connect the entire wind power plant to the power grid. If a wind power plant cannot connect to the grid, it simply cannot operate and will not be able to sell energy.

Furthermore, harmonics can cause many problems, such as overheating of electrical components, tripping of the protection and control devices as well as voltage distortion. These all can lead to significant energy losses and over time become rather expensive problems, for example as increased service and maintenance costs.

Both current and voltage harmonics are required to be within suitable ranges according to electrical standards and recommendations around the world.

Alternatives for harmonic mitigation

Harmonic mitigation can be achieved in various ways. For example, passive harmonic filters are one option. They are built using capacitor (capacitance) and reactor (inductance) elements and absorb the harmonic current to which they are tuned. Unwanted harmonics are trapped and get dissipated as heat rather than exported to the grid.

However, passive harmonic filters are not capable of dynamic compensation and they also have some fundamental frequency and operating losses. In addition, harmonics in wind power plants can constantly change based on the output and wind speed and passive filters are not able to keep up with that. These issues altogether limit the implementation of passive harmonic filtration equipment in wind power plants.

Active harmonic filtering is the way to go

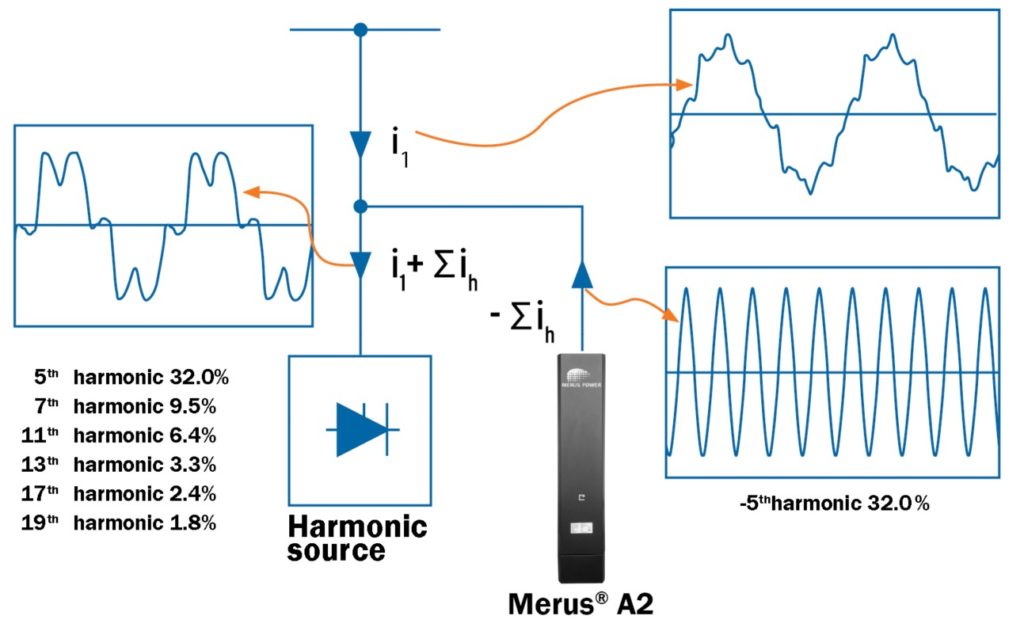

A more viable option is to use active harmonic filters to mitigate harmonics. In this case, offending harmonic currents are canceled or reduced by injecting inverse harmonic current in real-time into the system. Active harmonic filters are a much better option when the offending harmonic current is at multiple harmonic orders and these orders change over time as they do in wind farms. An additional advantage of an active harmonic filtering solution over a passive one is modularity, which helps with compensation capacity.

Merus® A2 – Mitigating harmonics and much more

Merus Power offers a modern active harmonic filtering solution. The reliable Merus® A2-Active Harmonic Filter can effectively solve all main problems in your electrical system. The best part — it is only one device.

Merus® A2 is a versatile solution, that can be easily tailored to a variety of applications and can meet even high compensation needs with its modular structure. Its extremely compact size and design allow clear and simple integration into a wide range of electrical systems.

Merus® A2 is a robust and fast-reacting solution for those who need quality. It uses well established 3-level IGBT topology which enables lower power losses, lower noise levels, and a smaller footprint.

Merus® A2 – Active Harmonic Filter

Merus® A2 is a scalable, versatile, and durable active harmonic filtering solution designed and manufactured in Finland using innovative Merus® technology.

Only one device, but multiple solutions to help you achieve…

- Significant energy and cost savings

- Higher productivity and reliability

- Decreased production downtime and work losses

- Extended lifetime of devices and components

- Reduced service and maintenance costs

- Compliance with recommendations and standards

- Compliance with grid code